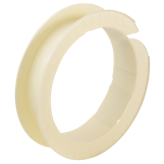

23 Spulen für Medizintechnik

Unter Reinraumbedingungen (Klasse D) produzierte Spulen für Schläuche.

| Bezeichnung | Flansch Ø | Kern Ø | Zentral-Bohrung Ø | Breite | Wickelbreite | Flanschdicke |

Wickel- volumen |

Z.-bohrungs Ø kegeliger Teil |

Mitnahme- einrichtung |

Mitnahme- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Spule MTL 395/221-240

Spule MTL 395/221-240

|

395 | 240 | 221 | 240 | 230 | 5 | 17780 | |||

Spule MT 396-205

Spule MT 396-205

|

396 | 210 | 205 | 92 | 80 | 4 | 7082 | |||

Spule MT 396-305

Spule MT 396-305

|

396 | 310 | 305 | 92 | 80 | 4 | 3814 | |||

Spule MTL 560/76-372

Spule MTL 560/76-372

|

560 | 315 | 76 | 372 | 362 | 5 | 60949 |